Waterproofing spray for outdoor adventures

The smartest way to use waterproofing spray and wash for tents, jackets and footwear! I usually get raindrops falling on my head, but since I waterproofed my gear, things...

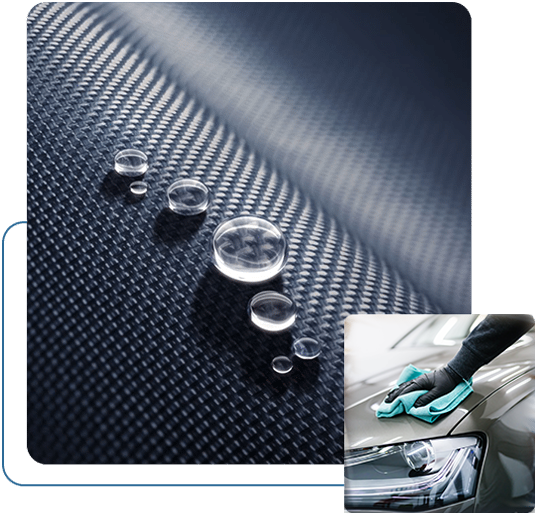

read moreA ceramic coating is a polymer coating that acts as a second skin to the paint layer to protect it from dust, UV rays, bird droppings, water droplets or scratches. Unlike waxes or silicones, the coating chemically bonds to the top layer of the paint, resulting in superior durability. That’s why there’s a ceramic coating lifetime warranty and no aftercare plan – it’s the most durable micro- and nanotechnology-based system in modern times.

The use of vehicles always involves risks regularly occur damage. Our Nanoflex ® Dura and Sapphire technologies provide a remedy.

Long-term protection in the automotive sector

Air cargo long-term protection in aviation:

Long-term protection in marine applications:

Depending on location, buildings are exposed to intense heat, frequent rainfall, humidity and snow. Interior surfaces are exposed to dirt and wear.

Architecture and construction long-term protection in the field of construction and architecture:

When companies make significant investments in industrial plant and equipment, they seek long-term, efficient and assured performance Our ceramic coating Nanoflex ® Dura and Nanoflex ® Sapphire provide resistant protection against corrosion, scale, wear and dirt In addition, they exhibit very high chemical stability.

Our ceramic coating consist of two types of systems organic preceramic or inorganic quartz.

Organic ceramics

Organic ceramics form dense ceramic layers with Si N Si and Si O Si structures As a result, the coatings are extremely heat resistant and provide excellent protection against corrosion and weathering In addition, water and dirt are repelled by the strong non-stick properties These properties also mean that paints hardly bond with the surface Thus, coated surfaces offer little grip for graffiti and removal of graffiti is made easy

Inorganic quartz

Inorganic quartz forms a film of silicon dioxide (similar to quartz or glass) and imparts anti-scratch properties to many substrates, as well as excellent chemical and heat resistance.

![]()

Drops and splashes don’t matter, a shower does, heavy rain even more so. Don’t turn outdoor into an adventure.

![]()

Once it has rained, cats, birds and deer are dry faster than you can look. Nano-Care With waterproofing brand you can do the same.

![]()

Wherever cleanliness is a priority, waterproofing does the best job due to its dirt-repellent properties. No matter whether on stone or textiles.

Easy-to-clean coating for flawless surfaces.

With a ceramic coating you make the lives of commercial customers, as well as consumers, easier by saving a lot of time and effort when it comes to cleaning cars, kitchens, ships or buildings.

Even the appearance of a well-maintained environment can be easily compromised:

The ceramic protective coating equips the material against frequent cleaning and contributes significantly to the reduction of soiling, saving not only time but also material costs in the long run.

Get in touch

The magic word is hydrophobicity, which describes the properties of Nanoflex ® Dura, Dura VF and Dura HD to repel water and maintain the good condition of the surface.

Want to know more about the properties of our products?

Get in touch

Even the slightest damage to surfaces, especially high gloss surfaces, is a curse Our solutions for improved scratch resistance provide the automotive construction and marine industries, as well as many other industries, with optimal surface protection.

Corrosion protection not only maintains the appearance of the surface, but also prevents future surface damage on steel or other metals. Surfaces protected by an effective anti-corrosion coating repel harmful elements and maintain their quality and appearance.

Get in touch

All product versions are supplied ready for use. Depending on the substrate, they can be applied with a microfiber applicator or paint roller ( microfiber flocking ). The product is also suitable for spray applications.

Spray application

Process: HVLP compressed air

Working pressure: approx. 2 3 bar

Nozzle: 0.8 1.3 mm

The spray gun can be cleaned with e.g. n Butyl Acetate

Storage stability: 12 months after delivery date, at 20 C

The substrate to be coated must be clean, free of grease and completely dry Difficult to access areas such as cavities or drainage channels etc should be blown dry with absorbent cloths or compressed air. In contact with damp substrate surfaces, a ceramic coating reacts prematurely and no permanent bond is formed with the substrate The substrate temperature and ambient temperature must be between +5°C and +30°C and the relative humidity between 30% – 80%.

Get in touch

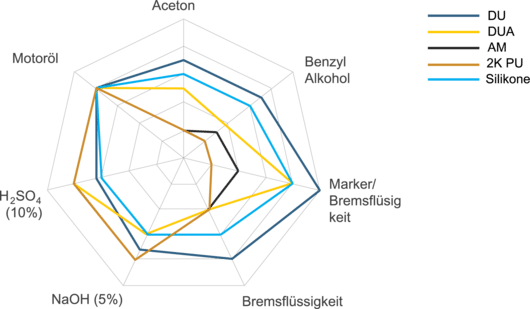

5: no effect – no noticeable change in the material surface.

4: Excellent – Slight detectable change in color or gloss, but no change in surface function or life.

3: Good – Significant discernible change in color or gloss, but no significant change in surface function or life.

2: Sufficient – Significant visual changes due to discoloration or etching possibly resulting in deterioration of function over an extended period of time.

1: Unsatisfactory – Pitting, cratering or erosion of the surface. Obvious and significant deterioration.

DU: Dura derivatives

DUA: Dura as additive in coatings

AM: Alkyd melamine system

PU: 2K Polyurethane System

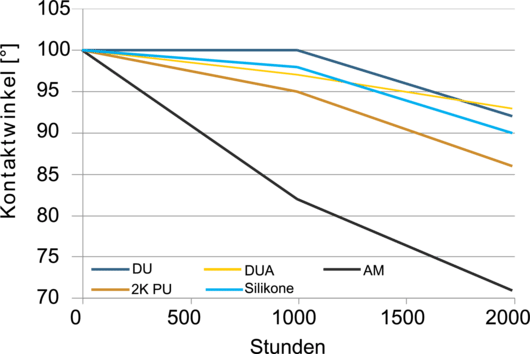

DU: Dura derivatives

DUA: Dura as an additive in coatings

AM: Alkyd melamine system

PU: 2K Polyurethane System

[su_tabs][su_tab title=”Product features” disabled=”no” anchor=”” url=”” target=”blank” class=””][table id=4 /][/su_tab]

[su_tab title=”Product features” disabled=”no” anchor=”” url=”” target=”blank” class=””][table id=5 /][/su_tab]

[su_tab title=”Suitable Surfaces” disabled=”no” anchor=”” url=”” target=”blank” class=””][table id=6 /][/su_tab][/su_tabs]

All safety instructions are detailed on the safety sheet and should be followed.

Storage

Ceramic sealants should be stored in a cool 10 C), dry place with adequate ventilation Ventilate the sealed container regularly (once a month) to reduce pressure. Ventilation data should be verifiable This measure reduces the accumulation of ammonia, hydrogen and self-igniting silane gas.

A very professional team!

Nanocare is a reputable company with excellent products, probably the best nanoproducts on the market.

They have been a reliable partner for many years.Toni Jacquot, NanoProtection, France

We were looking for an innovative company that could provide modern solutions in different business areas. Nano Care took the time to understand who we are as a company and the market in which we operate. So far, we have worked with their building and textile protection products, Dura ceramic coatings for automobiles, and the revolutionary Liquid Guard antimicrobial coating. The feedback we receive from our customers is more than satisfactory. We wholeheartedly recommend working with Nano Care and implementing their solutions.

Grigor Mihov , CEO Nano Coat Bulgaria

As Nano-Care AG sales partner in the international aviation market, we were able to successfully qualify and list the product with the Liquid-Guard technology by AIRBUS as the first product of this kind for the protection of surfaces against viruses and germs in all cabins.

The Liquid-Guard technology for surface coating is a proven result of scientific innovation “Made in Germany”, which will not only currently, but also in the future, play an important role in the protection of our health.

The service and the professional, scientific support as well as the cooperation for us as partners of Nano Care AG, we can only rate as outstanding and exemplary in every respect.

In particular, we would like to thank Dr. Fabienne Hennessen for her work.Jörg Schukies , AIRDAL GmbH / Decorative Products GmbH; Quality System Manager / Quality Auditor

The smartest way to use waterproofing spray and wash for tents, jackets and footwear! I usually get raindrops falling on my head, but since I waterproofed my gear, things...

read moreThis spray allows any type of bacteria to be killed on surfaces for a period of more than a year – even the “superbugs”! Every year we hear about...

read moreA hype or a profitable investment? Field report on ceramic sealants for cars The internet is full of questions like, “What is the best ceramic coating?” or “Are nano-ceramic...

read more