Field report ceramic sealants car

A hype or a profitable investment? Field report on ceramic sealants for cars

The internet is full of questions like, “What is the best ceramic coating?” or “Are nano-ceramic coatings worth the money?”. Especially in forums about car preparation, there is a lot of discussion about miracle coatings that offer protection and a shiny finish at the same time. But what is really behind this technology? How can I recognize high-quality brands?

In the post below, I’ll describe the chemical properties of durable products, separate fact from fiction, and take a look at the future of car reconditioning.

Below, I’ve answered 10 common questions found on the Internet:

#1. what is a ceramic sealant?

It is a polymer coating that acts as a second skin to the paint layer to protect it from dust, UV rays, bird droppings, water droplets or scratches. Unlike waxes or silicones, the coating chemically bonds to the top layer of the car paint, resulting in superior durability. For this reason, ceramic coatings come with a lifetime guarantee and no aftercare plan – it is the most durable system based on micro- and nanotechnology in modern times.

And here is the first surprise: there are two technologies available – organic and inorganic!

Whew! Now we first have to break down their respective properties to learn more about their impact on car paint.

Molecular structure of a Si-C-N ceramic coating

Molecular structure of a Si-C-N ceramic coating

Organic coatings have the following properties:

Chemically, it is a “pre-ceramic” coating, as original transparent ceramic material can only be made by curing at temperatures above 800 degrees, which I don’t think is applicable in real life.

Molecular structure of a quartz coating

Molecular structure of a quartz coating

Inorganic sealers are very different in comparison:

- Although they have a strong non-stick effect, they are not very water repellent. Therefore, companies that work exclusively with inorganic solutions also apply a finish or top coat to achieve a beading effect.

- The protective properties are excellent due to a non-porous cure. Unparalleled corrosion and scratch protection with a pencil hardness of 9H is easily achieved.

- The anti-graffiti effect is comparable to that of the organic variant.

And here is the second surprise from the chemical side: This protective technology consists only of inorganic quartz. That’s right, there is no ceramic layer at all. This application is quite complicated, as they are not compatible with any of the typical wetting agents or solvents used in paint technology. That’s why brands offer a “5 layer ceramic” – one layer doesn’t seem thick enough to act as a true paint coating.

The conclusion of the first answer:

Ceramic coatings work and outperform all available products, but at the end of the day, there is no ceramic on the body…but hey, if we as chemists created the marketing, the world would be a boring place. Now that you understand the two protective coating systems described above, you’ll probably want to know….

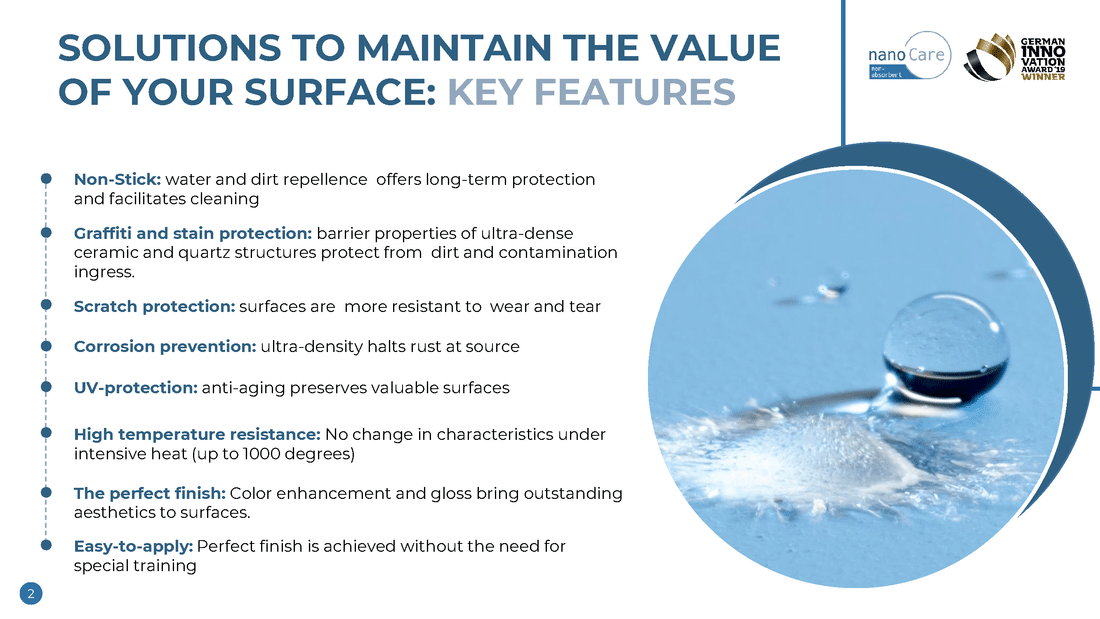

Main features of a ceramic sealant

Where can I find the best ceramic sealers?

The next surprise: the organic or inorganic raw materials that make up the polymers are produced in Germany or Japan. Now, you shouldn’t assume that a supplier outside of these countries is a fraud, but in terms of value for money, you’ll want to think about shipping and import costs. However, to be fair, the actual quality of paint coatings is based on the result of formulation with appropriate solvents and additives, which makes the country of origin less relevant.

By the way – I’ve noticed that there is a veritable glut of finishes marketed as ceramic paint coatings, but based on waxes or silicones. That means outdated material with a new label, could be considered a scam, since auto detailers usually don’t have all the knowledge covered in this article, and learn about durability and protection options mainly from videos on the Internet.

Silicones and waxes do not offer any of the described properties apart from a visually determinable water repellency. This property is mostly addressed by automotive industry influencers

How to find the best ceramic coatings

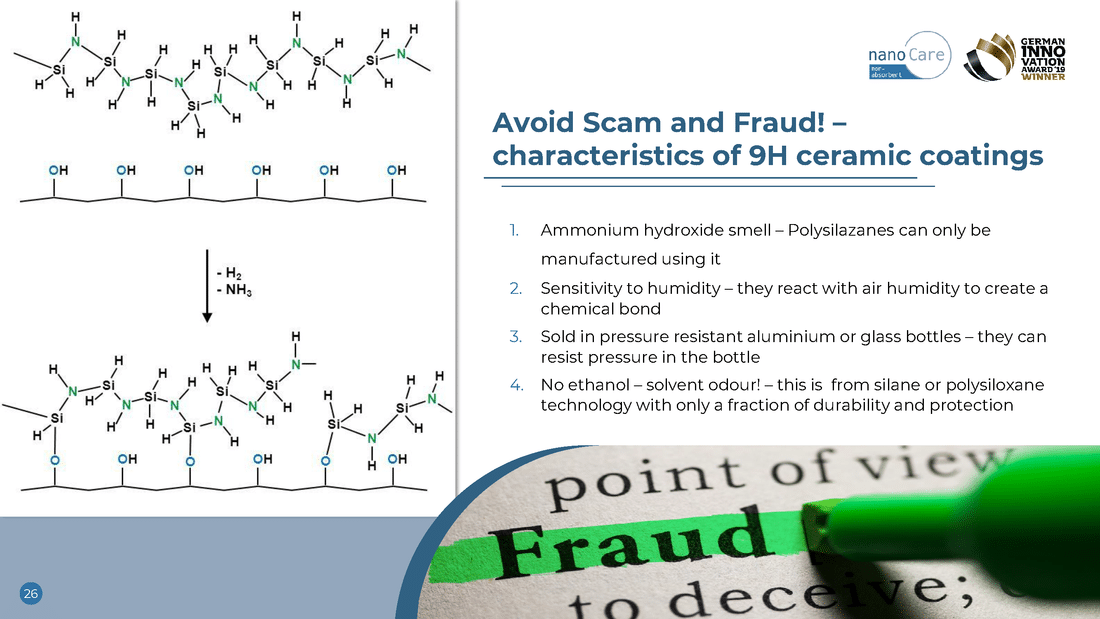

So how would an expert spot such a scam? A high quality paint sealant should:

[su_accordion][su_spoiler title=”Ammonium hydroxide Odor” open=”yes” style=”default” icon=”plus” anchor=”” anchor_in_url=”no” class=””]Have a strong ammonium hydroxide odor – organic and inorganic ceramic coatings cannot be made without ammonium hydroxide.[/su_spoiler] [su_spoiler title=”Humidity” open=”yes” style=”default” icon=”plus” anchor=”” anchor_in_url=”no” class=””]Be sensitive to moisture – they react with moisture in the air to create a chemical bond.[/su_spoiler] [su_spoiler title=”Aluminum or glass bottles” open=”yes” style=”default” icon=”plus” anchor=”” anchor_in_url=”no” class=””]Be sold in pressure resistant aluminum or glass bottles – pressure may be created in the bottle.[/su_spoiler][su_spoiler title=”IPA or ethanol base” open=”yes” style=”default” icon=”plus” anchor=”” anchor_in_url=”no” class=””]Not be IPA or ethanol based – such coatings are based on either silane or polysiloxane technology, which have only a fraction of the durability and protective capabilities of true ceramic coatings.[/su_spoiler][/su_accordion]

#3 What are the limitations?

Ceramic coatings do not protect in a car accident.

Ceramic coatings do not protect in a car accident.

The coating product is not self-cleaning. What makes a ceramic coating a “state-of-the-art” product is the “easy-to-clean” effect, with visible beading and release, but no superhydrophobic properties or self-cleaning effects in rain are present.

The coating will not help you avoid washing the car and it will not protect you in case of a car accident. We are talking about a coating thickness between 1-2 microns (inorganic) and 2-30 microns. If this coating were actually effective in preventing damage in car accidents, the next generation of cars would weigh only as much as a bicycle.

What is the difference between nano-coating, ceramic coating and diamond coating?

Not as hard as a diamond, but shiny bright like a diamond.

Not as hard as a diamond, but shiny bright like a diamond.

Ceramic coating and diamond coating are brand synonyms. I hope the brand name diamond refers to the shine effect and brilliance and not the hardness, because it is far from the 9H pencil hardness of a ceramic coating (up to 10 on the Mohs scale of a diamond).

Nano coatings for car paints, sold mainly in the years 2000-2008, protect car paint for a shorter period of time because they require many OH groups to bond. This makes them very effective as glass coatings for windshields, but not as paint protection.

Can it be applied as a “do-it-yourself” product?

DIY application of a ceramic coating.

DIY application of a ceramic coating.

If you search the internet, most articles say no. There are a few reasons forthis :

[su_spoiler title=”Hologram or rainbow effect.” open=”yes” style=”simple”]The composite nanoceramics are poorly formulated and leave a hologram or rainbow effect when applied without adequate training.[/su_spoiler][su_spoiler title=”Quality and certification.” open=”yes” style=”simple”]The brand wants to ensure quality or make money from its certification (usually both).[/su_spoiler][su_spoiler title=”Marketing reasons” open=”yes” style=”simple”]The paint protection is presented as exclusive for marketing reasons.[/su_spoiler]

Working at Nano-Care, in my experience, I can say that this product can be self-applied with a short, maybe 5-minute training. Most of the work is based on surface preparation.

How do I apply a ceramic coating and how long does it take?

Step 1: General cleaning with car shampoo or soap.

Step 2: Paint correction and clay bar (optional).

Step 3: Degreasing – removal of all residues on the surface of the vehicle.

Step 4: Application of the ceramic layer – put a few drops on a little absorbent microfiber cloth and spread the liquid without pressure. In most cases, rainbow effects occur, and you can let the liquid evaporate for 2-5 minutes. During this step, the coating absorbs the moisture in the air to bond with the car paint. Then carefully polish the surface with gentle movements until it is completely free of coating residues.

[su_note] Due to the reaction with humidity, it is important to control it at the time of application. 30-80% humidity is necessary to achieve proper results and adhesion. In addition, you should avoid temperatures below 10 and above 30 degrees Celsius. You can expect the surface preparation to take 3-12 hours and the coating of a medium size car to take 2-3 hours.[/su_note]

What is the cost of ceramic car coating?

Are there any new inventions or innovations that are still in development?

Yes, and my boss (regards to him) will probably not be happy that I am posting this video here:

It shows a transparent protective film with self-cleaning properties. Yes, you understand correctly – the future of car detailing will be to keep your car clean in one step – you need to refresh this super hydrophobic Nano-Care finish via simple spray. The film improves repellency from the petal effect to the Cassie-Baxter condition. Interested? I’ll be posting a new article on superhydrophobic coatings soon, so stay tuned.

This new generation of ultra-hydrophobic sealers solves a major problem that the Neverwet product could not solve in the past. That product left white residue on most car surfaces. This new super hydrophobic finish far surpasses those results.

For preliminary information, please contact my colleagues at Nano-Care.

Never wash a car again? nanoCare superhydrophobic ceramic coating finish

The future of car detailing and ceramic coatings: superhydrophobic nanoCare finish on car paint for a self-cleaning effect.

What are other applications of ceramic technology?

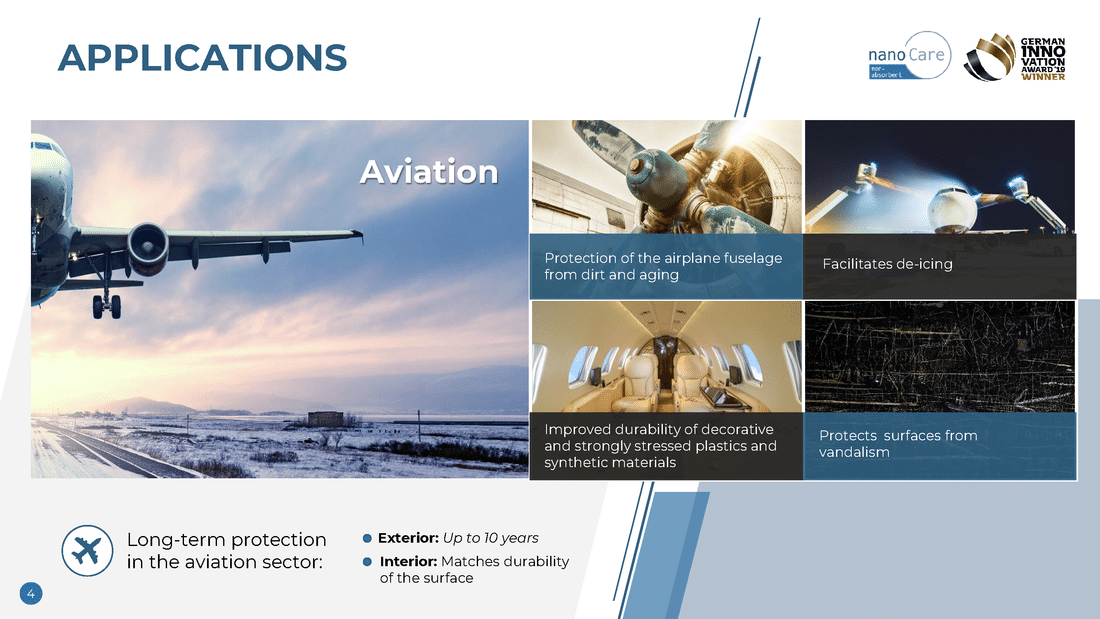

- Protects the aircraft fuselage from dirt and aging.

- Facilitates deicing

- Improves durability of decorative and heavy-duty plastics and other synthetic materials

- Protectsthe surface from vandalism

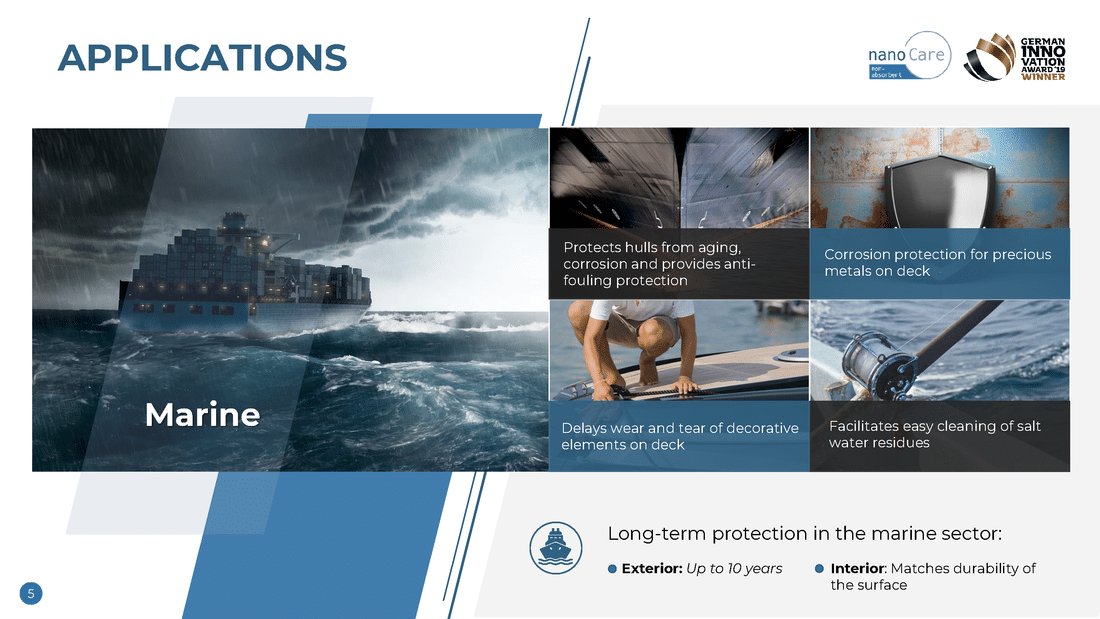

- Protects hulls from aging, corrosion and rotting

- Corrosion protection for precious metals on deck

- Delays the wear of decorative elements on deck

- Allows easy cleaning of salt water residues

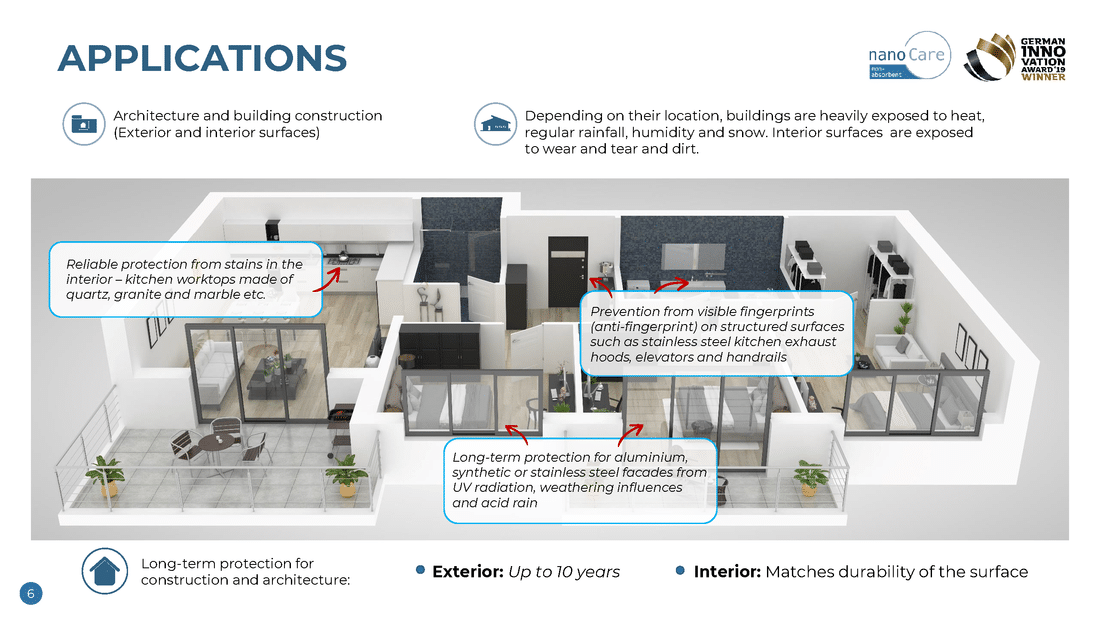

- Reliable protection against stains on interior kitchen countertops made of quartz, granite, marble, etc.

- Prevention of visible fingerprints (anti fingerprint) on textured surfaces such as hoods, elevators or stainless steel handrails.

- Long-term protection of aluminum, plastic or stainless steel facades against UV radiation, weathering and acid rain.

- Easy cleaning in food production (production lines, tanks, reactors).

- Non-stick coating for pipelines, reactors in the chemical industry, machines or commercial vehicles

- Easy biofilm removal

Can I see a case study?

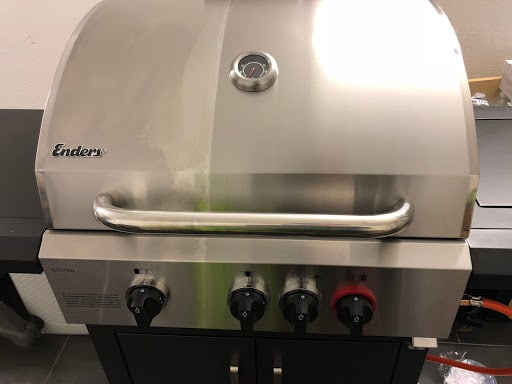

I did a “real life” test with my grill. For this, I coated the right half with the Nano-Care product Nanoflex Dura HD in May 2018.

Grill after applying the protective coating on the right side.

Grill after applying the protective coating on the right side.

Grill after 1 year without cleaning.

Grill after 1 year without cleaning.

Then I used it all summer, but left it outside without a cover. It also stayed outside in the fall without any further protection, except for the nanoceramic product. Winter came like Game of Thrones and in Germany we usually have wet and cold nights with snow and freezing temperatures. In addition, the grill was also not under a roof, so the forces of nature could rage for 12 months.

I was amazed myself: during use, you could already see that this experiment will turn out to be useful. The color of the aluminum quickly deepened – dried fingerprints or dried drops of rain or grease were hardly visible. And what’s more, the surface was as easy to clean as that of a PTFE-coated frying pan.

The result after a year, however, set new standards: incipient corrosion of the aluminum lid was nipped in the bud, and aging of the plastic lining was delayed. I only had to wipe the surface with a damp cloth once more before opening the grilling season this year.

”

I hope that with my first blog entry I was able to give you a deeper insight into the world of nanotechnology and microtechnology, especially nanoceramic coatings. For some readers, there may have been a surprise or two. If you enjoyed the article or have any questions, please write to me at drbommel@nano-care.com.